Baarka Filterka Birlabka

Baarka miiraha birlabku waa aalad caadi ahaan loo isticmaalo in lagu nadiifiyo wasakhaha dareeraha iyo gaaska.Qalabkani wuxuu caadi ahaan ka kooban yahay hal ama in ka badan ulo birlabeed ah oo qabta oo shaandhaysa wasakhda xadhkaha dareeraha ama gaaska si ay qalabka uga ilaaliyaan burburka.

Ulaha filter-ka magnetic waxay si fiican u shaandheyn karaan dareerayaasha, gaaska, budada iyo walxaha adag.Haddii ay daaweyso biyaha, saliidda, shidaalka ama istaarijka, dhalooyinka, macdanta, iwm, waxay heli kartaa natiijooyin wanaagsan.

Ulaha filter magnetic waxay leeyihiin hufnaan sifeyn wanaagsan.Sababtoo ah hantideeda xamasinta birlabeedka, waxay si wax ku ool ah u sifeyn kartaa wasakhda yaryar, sidaas awgeed waxay hagaajinaysaa tayada iyo nadiifnimada alaabta.

Ulaha filter magnetic way fududahay in la nadiifiyo, la ilaaliyo oo la beddelo.Sababtoo ah qaab-dhismeedkeeda fudud, si fudud ayaa loo kala diri karaa oo loo nadiifin karaa si loo ilaaliyo isticmaalka wanaagsan.Haddii ay u baahan tahay in la beddelo, si fudud u beddel baarka filter-ka magnetka.

Ulaha shaandhada magnetic waa kuwo dhaqaale iyo wax ku ool ah.Marka la barbardhigo filtarrada caadiga ah, ulaha filter magnetic uma baahna tamar dheeraad ah ama kharash waxayna u qaban karaan hawlaha sifeynta si dhakhso ah oo hufan, sidaas darteed hoos u dhigista kharashka wax soo saarka iyo kordhinta wax soo saarka.

Tilmaamaha Baarka Filterka Magnetka

Cabbirka: Cabbirka ulaha filter magnetic waa in lagu doortaa iyadoo loo eegayo cabbirka dhuumaha iyo shuruudaha socodka.Baaxadda waxaa badanaa lagu sifeeyaa cabbirro sida dhererka iyo dhexroorka.

| Shayga No. | Dhexroorka (mm) | Dhererka (mm) | Dusha sare (Gauss) | Shayga No. | Dhexroorka (mm) | Dhererka (mm) | Dusha sare (Gauss) |

| 25×100 | 25 | 100 | 1500-14000GS | 25×600 | 25 | 600 | 1500-14000GS |

| 25×150 | 25 | 150 | 1500-14000GS | 25×650 | 25 | 650 | 1500-14000GS |

| 25×200 | 25 | 200 | 1500-14000GS | 25×700 | 25 | 700 | 1500-14000GS |

| 25×250 | 25 | 250 | 1500-14000GS | 25×750 | 25 | 750 | 1500-14000GS |

| 25×300 | 25 | 300 | 1500-14000GS | 25×800 | 25 | 800 | 1500-14000GS |

| 25×350 | 25 | 350 | 1500-14000GS | 25×850 | 25 | 850 | 1500-14000GS |

| 25×400 | 25 | 400 | 1500-14000GS | 25×900 | 25 | 900 | 1500-14000GS |

| 25×450 | 25 | 450 | 1500-14000GS | 25×950 | 25 | 950 | 1500-14000GS |

| 25×500 | 25 | 500 | 1500-14000GS | 25×1000 | 25 | 1000 | 1500-14000GS |

| 25×550 | 25 | 550 | 1500-14000GS | 25×1500 | 25 | 1500 | 1500-14000GS |

Heerkulka: Maaddada iyo hoyga shaandhada birlabku waa inay awood u yeeshaan inay u adkeystaan heerkulka sare ama hooseeya ee deegaanka codsiga.

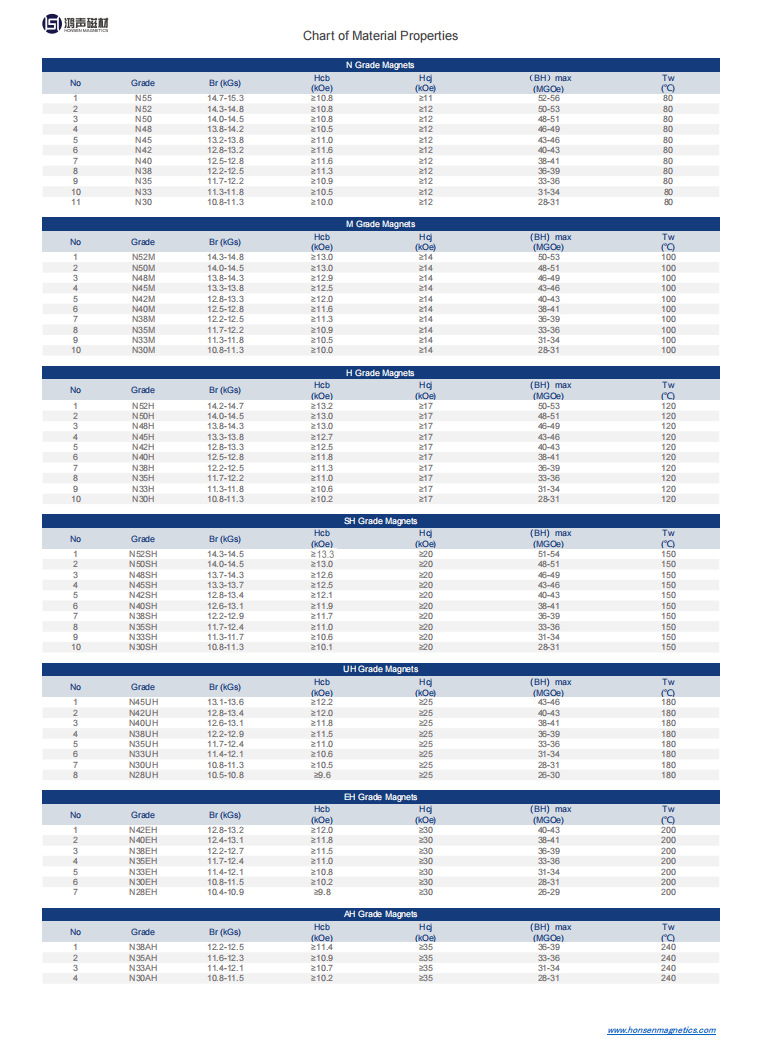

| Darajo | Max.Heerkulka shaqada | Curie Heer | darajada magnetic la taageeri karo |

| N | 80℃/176℉ | 310℃/590℉ | N30-N55 |

| M | 100 ℃/212 ℉ | 340℃/644℉ | N30M-N52M |

| H | 120 ℃/248 ℉ | 340℃/644℉ | N30H-N52H |

| SH | 150 ℃/302℉ | 340℃/644℉ | N30SH-N52SH |

| UH | 180 ℃/356℉ | 350℃/662℉ | N28UH-N45UH |

| Eh | 200℃/392℉ | 350℃/662℉ | N28EH-N42EH |

| AH | 240℃/464℉ | 350℃/662℉ | N30AH-N38AH |

Curie Temp: sidoo kale loo yaqaan Curie point ama barta kala-guurka magnetic, waa cabirka heerkulka shaqada ee shaqada ee walxaha magnetic, oo ka baxsan heerkulka Curie, sifooyinka birlabeed ee alaabta magnetic gabi ahaanba way baabi'i doonaan.

Heerkulka ugu badan ee shaqada: Haddii heerkulka shaqada ee ugu sarreeya la dhaafo, magnetismka walxaha magnetic waa la dhimi doonaa waxaana dhacaya khasaare aan laga soo laaban karin.

Xidhiidhka: marka uu sareeyo heerkulka Curie, waa uu sarreeyaa heerkulka shaqada ee maaddada, iyo sida wanaagsan ee xasiloonida heerkulka.

Xoogga Birlabka: Xoogga birlabeedka ee baar filter magnetic wuxuu ku xiran yahay nooca iyo tirada magnets-ka ku dhex jira.Xoog birlabeedka xooggan ayaa hagaajiya waxtarka sifaynta laakiin waxa kale oo laga yaabaa inay saamayso heerka socodka dareeraha ama gaaska.

Walxaha: Maaddada usha shaandhada birlabku waa inay la jaanqaadaan dareeraha ama gaasta la sifeynayo waana in aanay noqon mid daxal ah.

Sababtoo ah iska caabbinta daxalka oo aad u fiican, birta aan la taaban karin ayaa ah shay caadi ahaan loo isticmaalo codsiyo badan.Si kastaba ha ahaatee, codsiyada u baahan heerka sare ee caabbinta daxalka, sidoo kale waa muhiim in la doorto darajo sare oo ah walxaha birta ah.Tusaalooyinka waxaa ka mid ah 316 ama 316L, kuwaas oo si gaar ah ugu habboon warshadaha sida cuntada ama farsamaynta kiimikada, halkaasoo soo-gaadhista kiimikooyinka adag ama huurka sare ay dhici karto.

Haddii aadan hubin midka ugu habboon baahiyahaaga codsi, fadlan xor u noqo inaad nala soo xiriirto.Kooxdayada khubarada ahi waxay ku siin karaan talo iyo tilmaamo kaa caawinaya inaad gaadho go'aan xog ogaal ah.Honsen, waxaa naga go'an inaan hubino inaad hesho alaabta ugu fiican ee codsigaaga, waxaana mar walba halkan u joognaa inaan ku caawino.

Rakibaadda:

Dhamaadka birlabku wuxuu leeyahay dunta lab

Dhamaadka birlabku wuxuu leeyahay dunta dheddigga

Cidhifyada birlabku waa siman yihiin

Labada daraf ee magnet-ka ayaa si gaar ah loogu dhejin karaa si ay u buuxiyaan shuruudahaaga gaarka ah, oo leh xulashooyin sida lab, dheddig, iyo alxan fidsan.Wax kasta oo aad u baahan tahay, waxaan ku siin karnaa magnet sax ah si aan u hubinno habka rakibida ee aan kala go 'lahayn.

Sidee si sax ah loo dooran karaa shaandhada magnetic saxda ah?

Heerka socodka: Go'aami heerka socodka iyo heerkulka hawlgalka ee u baahan in la sifeeyo.Tani waxay kaa caawinaysaa in la go'aamiyo inta ulaha filter magnetic ee loo baahan yahay iyo nooca ulaha filter magnetic.

Xoogga Magnetic: Dooro xoogga birlabeedka habboon ee ku saleysan nooca iyo cabbirka wasakhda la saarayo.Caadi ahaan, ulaha filter magnetic xoog badan ayaa looga baahan yahay walxaha ka sii weyn.

Qaabka: Dooro qaabka shaandhada birlabeedka ee ku habboon si waafaqsan booska rakibaadda dhabta ah iyo shuruudaha qalabka shaandhada.

Qalabka: Dooro walxo ku habboon si aad ugu habboonaato warbaahinta dareeraha ah ee kala duwan iyo jawiga, sida birta aan lahayn, daawaynta titanium, walxaha magnetka joogtada ah, iwm.

Nolosha iyo kharashka dayactirka: Dooro ulaha filter magnetka leh nolol dheer iyo kharashka dayactirka yar si loo yareeyo kharashka isticmaalka iyo kharashka dayactirka.

Codsiga bar filter magnetic

Warshadaha caaga ah: Ulaha filter magnetic waxaa inta badan loo isticmaalaa in nidaamka wareegga qaboojinta ee mishiinada qaabaynta irbado, extruders, mashiinada qaabaynta iyo qalab kale si ay meesha uga saarto chips birta, budada birta iyo wasakh kale si loo ilaaliyo shaqada caadiga ah ee qalabka.

Warshadaha dawooyinka: Ulaha filter magnetic waxay ka saari karaan wasakhda sida jajabyada birta iyo birta birta ah ee dawooyinka dareeraha ah si loo hubiyo nadiifnimada iyo tayada daawooyinka.

Warshadaha cuntada: Ulaha filter magnetic ayaa si weyn loogu isticmaalaa khadadka wax soo saarka cuntada si looga saaro wasakhda birta ah ee cuntada si loo hubiyo tayada iyo badbaadada alaabta.

Warshadaha farsamaynta: Ulaha shaandhada magnetic waxaa badanaa loo isticmaalaa qaboojiyaha qalabka si looga saaro jajabyada birta, ciidda iyo wasakhda kale si loo kordhiyo nolosha qalabka loona wanaajiyo saxnaanta mashiinka.

Warshadaha gaaska: Ulaha filter-ka magnetka ayaa ka saari kara jajabyada birta iyo wasakhda kale ee ku jirta gaaska dabiiciga ah iyo gaaska dareeraha ah si loo ilaaliyo shaqada badbaadada leh ee qalabka gaaska.

Warshadaha Kiimikada: Waxaa loo isticmaalaa in laga saaro qaybaha ferromagnetic iyo oksaydhyada ee ku xayiran xalka.

Warshadaha waraaqaha: waxaa loo isticmaalaa in lagu saaro wasakhda ferromagnetic ee habka waraaqaha si loo hubiyo tayada waraaqaha.

Warshadaha macdanta: waxaa loo isticmaalaa in lagu kala saaro macdanta ay ku jirto birta iyo macdanta iyo hagaajinta waxtarka habaynta macdanta.

Warshadaha daaweynta biyaha: ulaha filter magnetic iyo baararka ayaa ah qalab wax ku ool ah oo lagaga saaro birta, manganese iyo biraha kale ee biyaha, taas oo ka dhigaysa mid ammaan u ah cabitaanka iyo isticmaalka kale.

Warshadaha Dharka: Ulaha filter-ka magnetka ah iyo baararka waxaa loo isticmaalaa wax soo saarka dunta si looga saaro wasakhda biraha ee maryaha, hubinta tayada alaabta iyo ka hortagga waxyeelada mashiinada.

Warshadaha baabuurta: Ulaha filter magnetic waxaa loo isticmaalaa soo saarista baabuurta si looga saaro wasakhda birta ee qaboojiyaha iyo saliidaha si looga hortago waxyeelada qalabka loona hubiyo tayada alaabta.

Faa'iidooyinkayaga

U hel baararka filter-ka magnetic wareegsan ee qumman ee baahiyahaaga!Ulaha birlabkeena waxa lagu heli karaa codsi gaar ah.

Ulaha filter magnetic 1.Our iyo baararka waxaa laga sameeyey tuubo bir ahama oo tayo sare leh oo ay la socdaan waxqabadka sare ee neodymium magnets si ay u habboon codsigaaga gaarka ah.Adigoo isticmaalaya ulaha shaandhada birlabeedka gaarka ah, waxaad dhisi kartaa ama wax ka beddeli kartaa qalabkaaga kala-saarista birlabeedka.

2. Dooro xoogga magnetka ee ku habboon baahiyahaaga!Badeecadahayagu waxay ku diyaarsan yihiin xoog birlabeedka 1500-14000 gauss si loo buuxiyo shuruudahaaga gaarka ah.Baararka ku qalabaysan birlabyada neodymium ee xooggan waxay yeelan karaan qiyamka magnetic ilaa 14,000 gaus oo korkooda ah.

3.A ku habboon ulahayaga si buuxda loo shaabadeeyey iyo kuwa welded!Waxaan bixinaa darafyo alxan leh oo lab ah, dheddig ama fidsan si loo buuxiyo shuruudahaaga gaarka ah.

4.Dhammaan baararka magnetic waa kuwo aan biyuhu lahayn, iyaga oo hubinaya in ay si wax ku ool ah u shaqeeyaan xitaa meelaha qoyan ama qoyan.

5.Our filter filter magnetic iyo ulo ayaa si fiican u dhalaalaya si ay u bixiyaan muuqaal xirfad leh iyo si loo hubiyo in ay fududahay in la nadiifiyo oo la ilaaliyo.

Qalabkayaga tayada leh iyo xulashooyinka dabacsan, waxaad si kalsooni leh u dhisi kartaa ama wax uga beddeli kartaa qalabkaaga kala-soocidda magnetic.

Waqtiga boostada: Abriil-13-2023