Goobta codsiga ugu weyn eebirlabyada joogtada ah ee dhulka naadirwaa matoorrada birta ah ee joogtada ah, oo loo yaqaan matoorada.

Matoorada dareenka ballaaran waxaa ka mid ah matoorrada tamarta korontada u beddela tamar makaanik ah iyo koronto-dhaliyeyaasha tamarta farsamada u beddela tamar koronto. Labada nooc ee matoorada waxay ku tiirsan yihiin mabda'a kicinta korantada ama xoogga korantada sida mabda'ooda aasaasiga ah. Goobta magnetic-gap-ka hawada ayaa shardi u ah hawlgalka matoorka. Matoorka abuura gaab magnet-ka-hawo-magnet-ka ah iyada oo loo marayo kicinta waxaa loo yaqaan 'induction motor', halka mootada soo saarta gaabka magnetka hawada-gaab ee magnet joogto ah loo yaqaan magnet joogto ah.

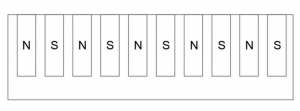

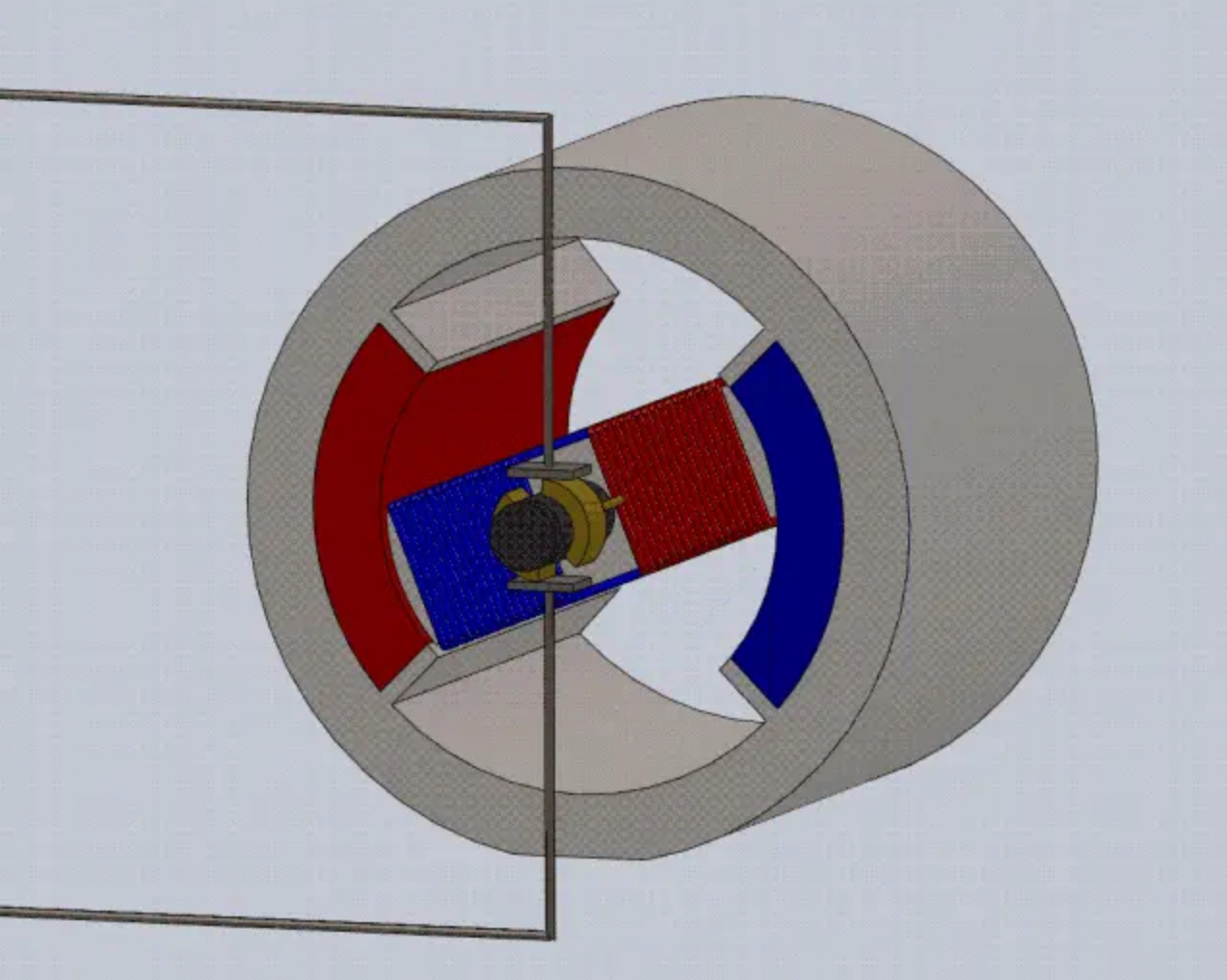

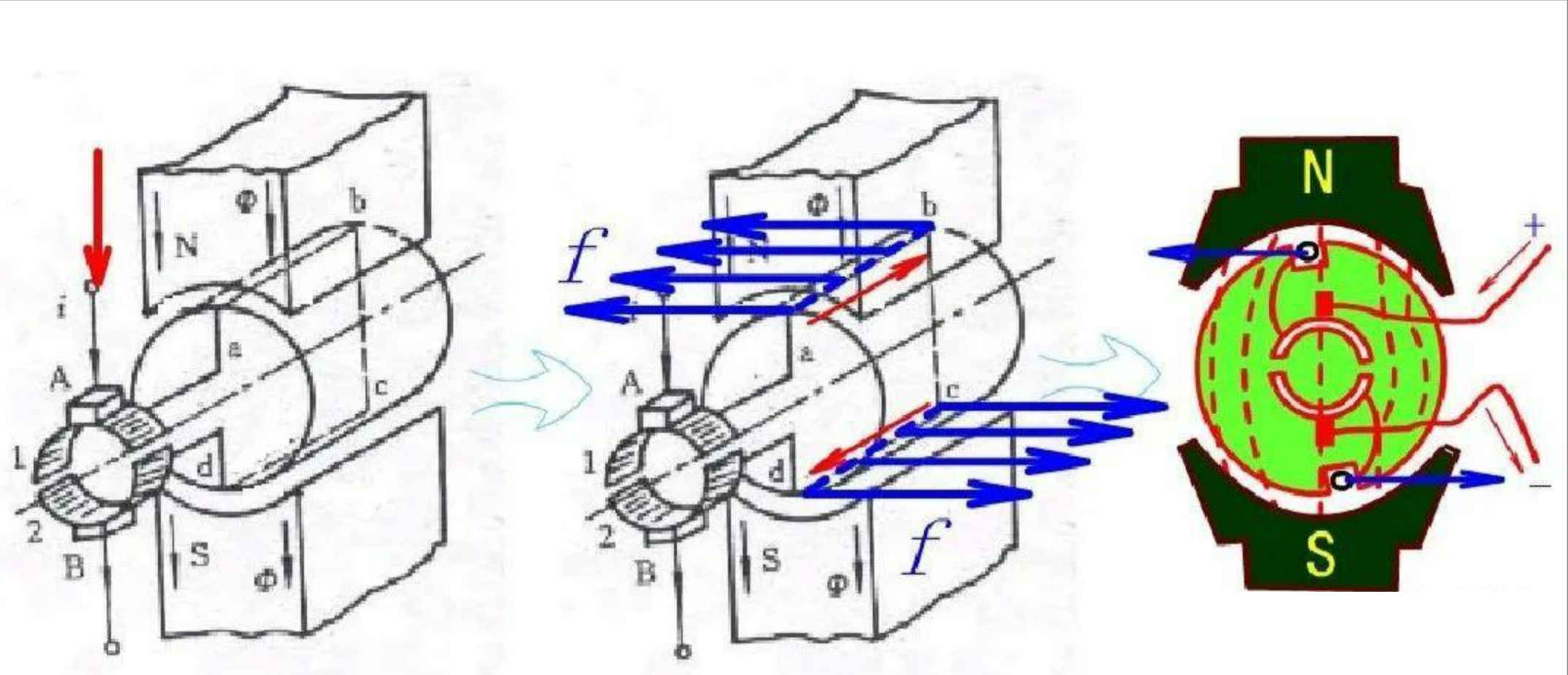

Matoorka birlabeedka joogtada ah, garoonka magnetic-gap-ka hawada waxaa dhaliya birlab joogto ah iyada oo aan loo baahnayn koronto dheeri ah ama dabaylo dheeraad ah. Sidaa darteed, faa'iidooyinka ugu weyn ee matoorrada magnetka joogtada ah ee matoorada kicinta waa waxtarka sare, badbaadinta tamarta, cabbirka is haysta, iyo qaab dhismeedka fudud. Sidaa darteed, matoorrada magnetka joogtada ah ayaa si weyn loogu isticmaalaa matoorrada yaryar iyo kuwa yaryar ee kala duwan. Jaantuska hoose waxa uu tusinayaa qaabka hawlgalka ee la fududeeyay ee matoorka DC ee joogtada ah. Laba birlab joogto ah ayaa soo saara goob birlab ah oo ku taal bartamaha gariiradda. Marka gariiraddu tamar yeelato, waxa ay la kulantaa xoogga korantada (sida uu qabo qaanuunka gacanta bidix) oo wareego. Qaybta wareega ee matoor koronto waxaa lagu magacaabaa rotor, halka qeybta taaganna loo yaqaan stator. Sida laga arki karo shaxanka, magnets-ka joogtada ah ayaa iska leh stator, halka gariiradu ay leeyihiin rotor.

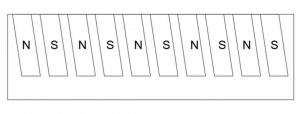

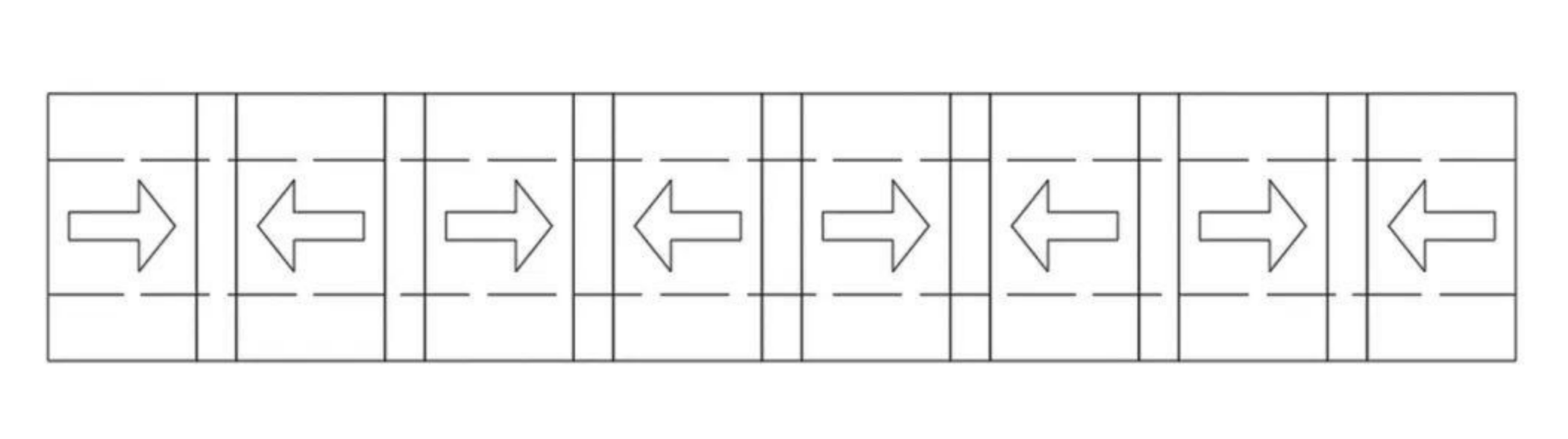

Matoorada rotary, marka magnet joogto ah waa stator, waxaa sida caadiga ah la soo ururiyey in qaabeynta #2, halkaas oo magnets ku lifaaqan guryaha motor. Marka magnet-ka joogtada ahi uu yahay rotor-ka, waxa caadi ahaan la isugu geeyaa qaabaynta #1, iyadoo magnets-ku ku dheggan yahay xudunta rotor-ka. Haddii kale, qaabaynta #3, #4, #5, iyo #6 waxay ku lug leedahay dhex gelinta magnets-ka xudunta rotor-ka, sida ku cad jaantuska.

Matoorada tooska ah, magnets-ka joogtada ahi waxay ugu horrayn u qaabaysan yihiin labajibbaaran iyo barbar-yaal. Intaa waxaa dheer, matoorrada tooska ah ee cylindrical waxay isticmaalaan birlab-magneteed-magnetized anular ah.

Magnet-yada ku jira Motor Magnet Joogtada ah waxay leeyihiin sifooyinka soo socda:

1. Qaabku aad uma dhib badna (marka laga reebo matoorada yar yar, sida matoorada VCM), badi ahaan leydi, trapezoidal, fan-qaabeeya, iyo foomamka qaabka rootiga. Gaar ahaan, dhismaha dhimista kharashyada naqshadaynta mootada, qaar badan ayaa isticmaali doona magnet-ka labajibbaaran ee ku xidhan.

2. Magnetization-ku waa mid fudud, inta badan magnetization hal tiir ah, ka dib marka la isku yimaado, waxay sameysaa wareegga birlab-badane ah. Haddii uu yahay giraan dhammaystiran, sida giraanta boron-ka birta neodymium ee xabagta ah ama giraanta kulaylka lagu riixo, badanaa waxay qabataa magnetization shucaaca badan ee tiirarka.

3. Xuddunta shuruudaha farsamada inta badan waxay ku jirtaa xasilloonida heerkulka sare, joogteynta qulqulka magnetic, iyo la qabsiga. Mashiinnada rotor-ka dusha sare ku rakiban waxay u baahan yihiin sifooyin dhejis ah oo wanaagsan, magnets-yada tooska ah waxay leeyihiin shuruudo sare oo loogu talagalay buufinta milixda, koronto dhaliyaha dabaysha waxay leeyihiin xitaa shuruudo adag oo loogu talagalay buufinta milixda, iyo magnets-ka gawaarida waxay u baahan yihiin xasillooni heerkul sare leh.

4. Alaabada tamarta magnetic heer sare, dhexdhexaad ah iyo heer hoose ah ayaa dhamaantood la isticmaalaa, laakiin jujuubku inta badan waa dhexdhexaad ilaa heer sare. Waqtigan xaadirka ah, darajooyinka magnetka ee sida caadiga ah loo isticmaalo matoorrada wadista baabuurta korontada ayaa inta badan ah alaabada tamarta magnetic sare iyo qasbidda sare, sida 45UH, 48UH, 50UH, 42EH, 45EH, iwm, iyo tignoolajiyada fidinta qaangaadhka ah waa lagama maarmaan.

5. Magnet-yaasha dahaadhay ee koollada ah ee qaybsan ayaa si weyn loogu isticmaalay garoonnada matoorrada heerkulka sare leh. Ujeeddadu waa in la hagaajiyo dahaadhka kala-soocidda birlabadaha oo la dhimo khasaaraha hadda jira inta lagu jiro hawlgalka mootada, iyo magnets-yada qaarkood waxay ku dari karaan daahan epoxy dusha sare si ay u kordhiyaan dahaarkooda.

Waxyaabaha muhiimka ah ee tijaabinta magnets-ka motor:

1. Dejinta heerkulka sare: Macaamiisha qaarkood waxay u baahan yihiin cabbiraadda suuska magnetic-circuit-furan, halka kuwa kalena ay u baahan yihiin cabbiraadda suuska magnet-ka-furan. Inta lagu jiro hawlgalka mootada, magnets-yadu waxay u baahan yihiin inay u adkeystaan heerkulka sare iyo beddelka dhulalka birlabeedka. Sidaa darteed, tijaabinta iyo la socodka alaabada dhammaatay ee suuska magnetic iyo heerkulka sare ee demagnetization qalooca alaabta salka ayaa lagama maarmaan ah.

2. Joogteynta qulqulka magnetic: Sida isha meelaha magnetic-ka ee rotors-ka ama stators, haddii ay jiraan is-khilaafyo ku jira qulqulka magnetic, waxay sababi kartaa gariir mootada, iyo hoos u dhigista awoodda, waxayna saameyneysaa shaqada guud ee matoorka. Sidaa darteed, birlababka mootada guud ahaan waxay leeyihiin shuruudo joogteynta qulqulka magnetic, qaar 5% gudahooda, qaar 3% gudahooda, ama xitaa 2%. Waxyaabaha saameeya joogteynta qulqulka magnetic, sida joogteynta magnetismka haraaga ah, dulqaadka, iyo daahan chamfer, waa in dhamaantood la tixgeliyo.

3. La qabsiga: Magnets-ku-dhejinta dusha sare waxay u badan yihiin qaab tile ah. Hababka baaritaanka caadiga ah ee laba-geesoodka ah ee xaglaha iyo radiyadu waxay yeelan karaan khaladaad waaweyn ama ay adag tahay in la tijaabiyo. Xaaladahan oo kale, la qabsiga ayaa loo baahan yahay in la tixgeliyo. Magnets-ka si dhow loo habeeyay, daldaloolada is biirsaday waxay u baahan yihiin in la xakameeyo. Magnet-yada leh boosaska qoolleyda, adkeynta isku-dhafka ayaa loo baahan yahay in la tixgeliyo. Way fiicantahay in la sameeyo qalab qaabaysan sida waafaqsan habka isu-ururinta isticmaalaha si loo tijaabiyo la qabsiga birlabadaha.

Waqtiga boostada: Agoosto-24-2023